Just Released! Die Casting Congress Show Guide for 2018

Multiple Spindle Tapping of Die Castings

Most Die Castings have multiple holes that must be tapped. Many times there are different size tapped holes in the same face of the casting. Frequently these holes are tapped to different depths. Sometimes these tapped holes are on multiple faces of the casting. This can make tapping a complex and costly secondary operation.

Many people believe they must tap their Die Castings on CNC Machining Centers to tap different size taps to different depths on multiple faces of their Die Castings.

There are alternatives to using CNC Machines for these tapping operations. Jost Machinery has Multiple Spindle Tapping Machinery that is faster and more economical than multiple CNC Machines. Individual Lead Screw Spindles are preset to the tap depth and repeat very accurately. Spring compensating Spindle Drivers allow the lead screw spindles to match the feed of the tap. An electric brake motor drives the system, and it is all electrically controlled. The tapping cycle is usually under (4) seconds with a total machine cycle of (10) seconds, including manual unload/reload of the Die Castings in the fixture.

How Would You Tap These Holes?

Aluminum Die Cast Bracket with Complex Hole Pattern

Aluminum Die Cast Bracket with Complex Hole Pattern

The parts are high volume Aluminum Die Castings. All (6) holes are cored to different depths, with some blind holes.

The taps are all rollform taps. They are (1) M8 x 1.25, (2) M6 x 1.0 and (3) M10 x 1.5 tapped holes… And the holes are (3) different depths.

Our customer had been tapping the holes on a CNC Machining Center with pallet changer. The CNC Machine had to tool change (3) times for each part. They made great parts, but the cost of tapping these holes was too high, and they couldn’t tap fast enough to keep up with the Die Cast process.

They asked Jost Machinery if we could help them make good parts, faster, and less expensively.

Multiple Spindle Tapping of Die Castings

Multiple Spindle Tapping Machine Complete with

Automatic Fixture and Controls

The solution is a Multiple Spindle Tapping Machine with Individual Lead Screw Tapping Spindles, Automatic Clamping and Automatic Cycle!

This machine taps all (6) holes simultaneously in (10) seconds part-to-part, or 360 parts per hour.

Our customer freed-up a horizontal CNC Machining Center for a new casting with the machine shown in this picture. The Individual Spindle Lead Screw Tapping Machine taps different size holes, on close centers, with total depth control, 10 seconds part-to-part, greatly increasing the production rate while saving the purchase of another CNC machining center.

3-Way Multiple Spindle Tapping Machine

3-Way Tapping Machine for a Die Cat Engine Cover

This photo shows a 3-Way Tapping Machine that ran next to a CNC Machining Center. The same operator ran both machines with a much shorter machine cycle by tapping offline. In fact, the customer saved the cost of an additional CNC by purchasing this 3-Way Tapper.

4-Way Multiple Spindle Tapping Machine

Front View of 4Way Tapping Machine for Die Cast Housings

Top View of 4Way Tapping Machine for Die Cast Housings

These photos show another good application of Individual Spindle Lead Screw Tapping of Die Cast Housings from (4) different directions. The tapped holes were cored and this was the only Secondary Machining Operation required. Note: all holes were tapped simultaneously at a rate of (300) parts per hour.

Individual Lead Screw Tapping provides:

· Lead Screw Control of feed rate and depth for each tap

· Quick Change Tap Holders with Float

· Quick Change Spindle Plates for various parts

· Rapid approach when required

· Taps all holes in the faces of the Die Casting

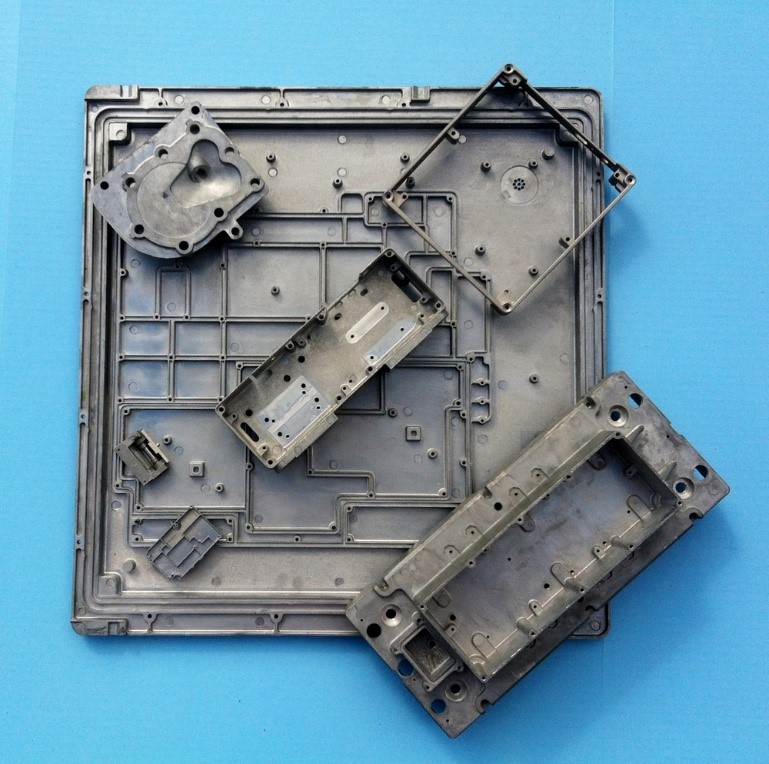

Die Castings tapped using multiple spindle tapping.

Individual Spindle Lead Screw Tapping is accurate and precise for small taps and high-torque for large taps. It can be used for rollform or cut taps. It frequently is used to tap cored hole in die casting.

Cutting Costs When Tapping Die Castings

Are you trying to cut costs to keep your customer happy? Are you trying to quote new jobs where they want you to do the machining for free? Do you have a rush job to tool up? We will help you with all of these things.

Ask for help…

It is recommended that you share the burden of your analysis as you develop the machining processes of your Die Castings or quote new parts to your customers. Castings, cast drawings, machining drawings, production rate and start up dates provide the necessary information for outside analysis. By drawing on the knowledge and experience of others you will be able to develop multiple machining processes and to determine the best machining system on time and on budget.

About the Author

Vic Jost is President of Jost Machinery Co. in Ellisville, MO. He has many years of experience developing machining systems for die casting companies. He is an Industrial Engineer by training with extensive experience analyzing die casting tolerances, locating and clamping requirements, production volumes, delivery schedules and budget restrictions to optimize the machining system for each die casting program.