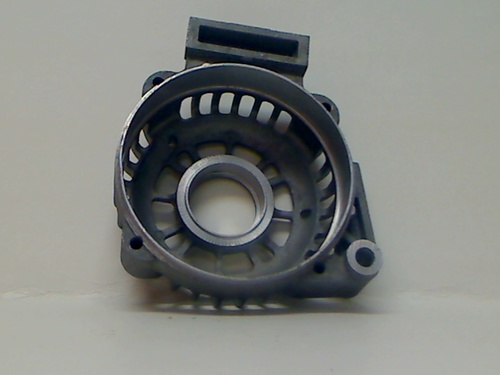

Cost is always a driver on automotive projects. Short cycle times are also a goal, but one constant is quality. The diameters and concentricity’s of the bores of alternator housings are tight!

The Jost Solution did not utilize CNC lathes because they would be too slow and too expensive. We recommended using cluster boring tools with thru the tool coolant for high metal removal rates and the use of diamond tooling. The process was fast and complete with only one operator required. Everything was optimized with material handling during the machining cycle, roughing and finishing occurred simultaneously, and coolant fed cluster tools tripled metal removal rates compared to CNC lathes.

If you are looking for ideas, let’s talk!

1-800-222-960