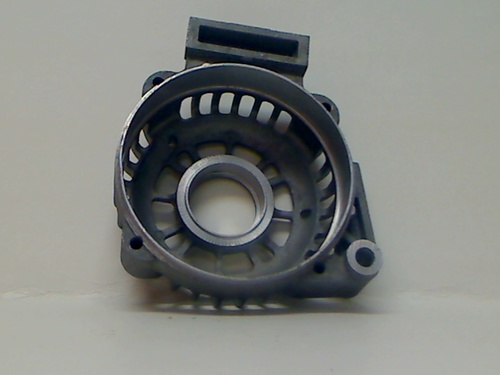

The part is actually three identical pieces of aluminum all made from one part. It is a military product made to exact specifications. We helped develop the machining processes over a period of years.

Originally, we focused on the workholding of their CNC lathes. They needed a better way to hold the aluminum bar than a conventional power chuck. Later, we focused on cutting the part into three pieces.

The Jost Solutions were actually quite simple. We applied standard products which had already answered these problems. The result was they achieved customized solutions at a bargain price.

When you are looking for ideas, let’s talk! 1-800-222-9607